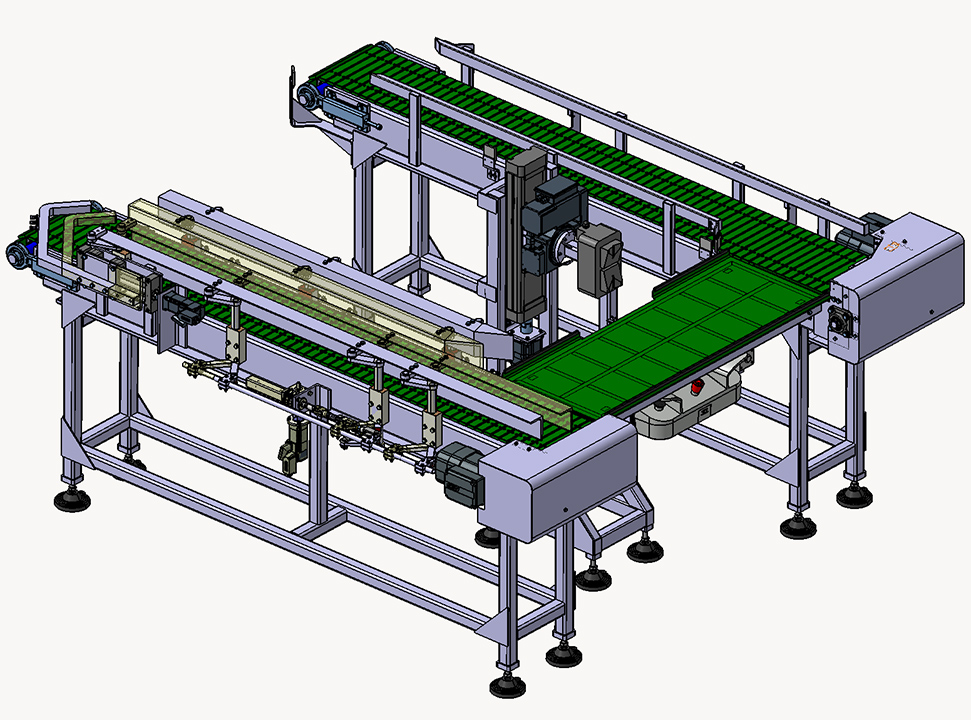

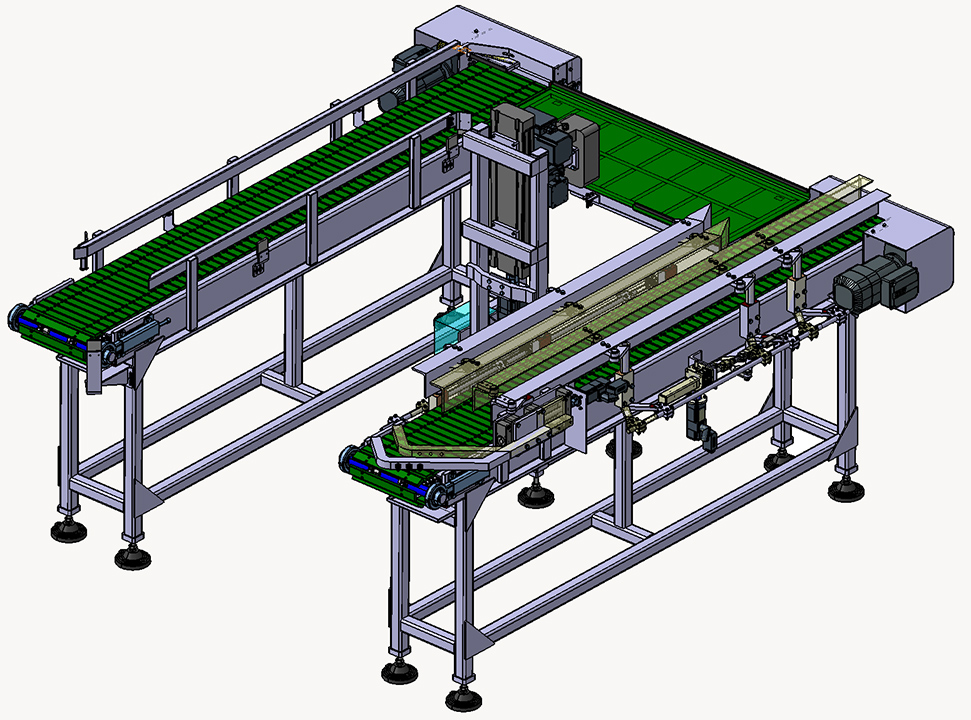

The process of accurate measuring starts with analyzing subjected parts and assemblies. Eventually this leads to designing optimum measuring or control concept exactly according to the actual conditions.

We use modular system by Carl Zeiss when designing our jigs that allows us to achieve guaranteed accuracy of 0.05 mm.

This system brings several advantages including easy adjustment, flexible adaptability and high accuracy of measuring. We are able to create measuring jigs of various size, geometry and even materials. We design special, control, life cycle and detection measurement jigs.