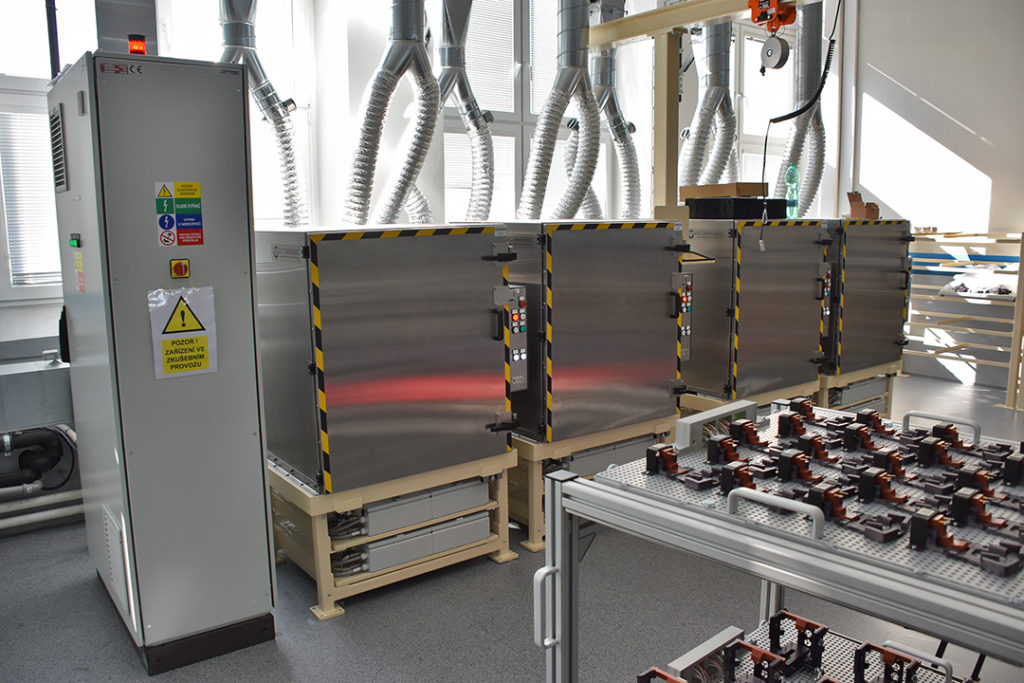

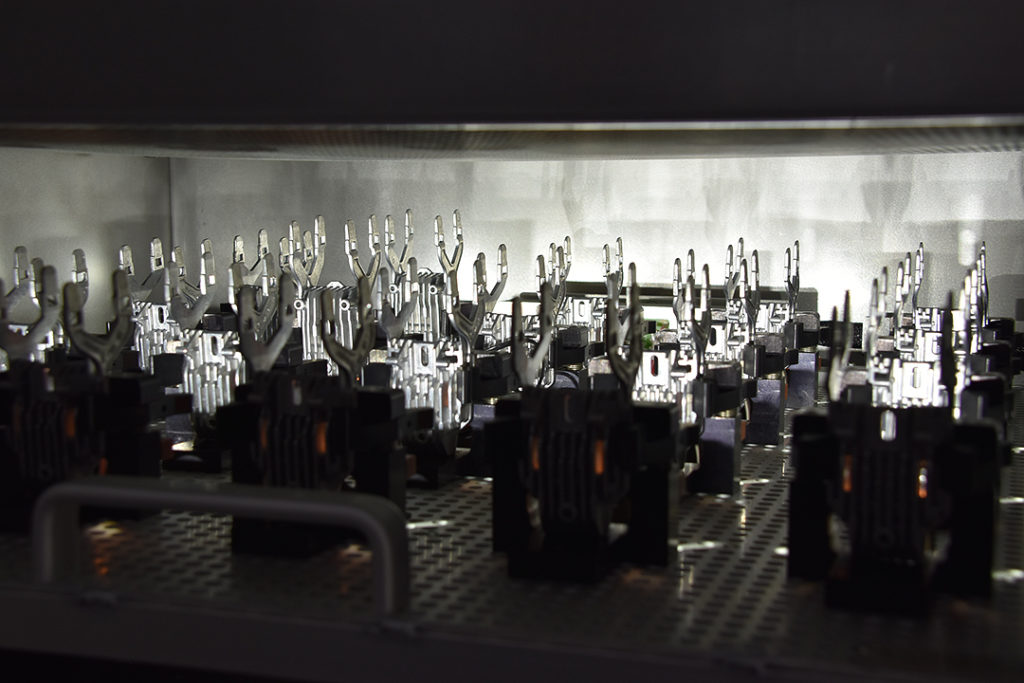

Every single LED light fitting is put into JIG attached to technological pallet and smoke tested in chambers with regulated temperature. Every pallet has connectors of every JIG for voltage income to chamber and for monitoring changes of electric variable during the test.

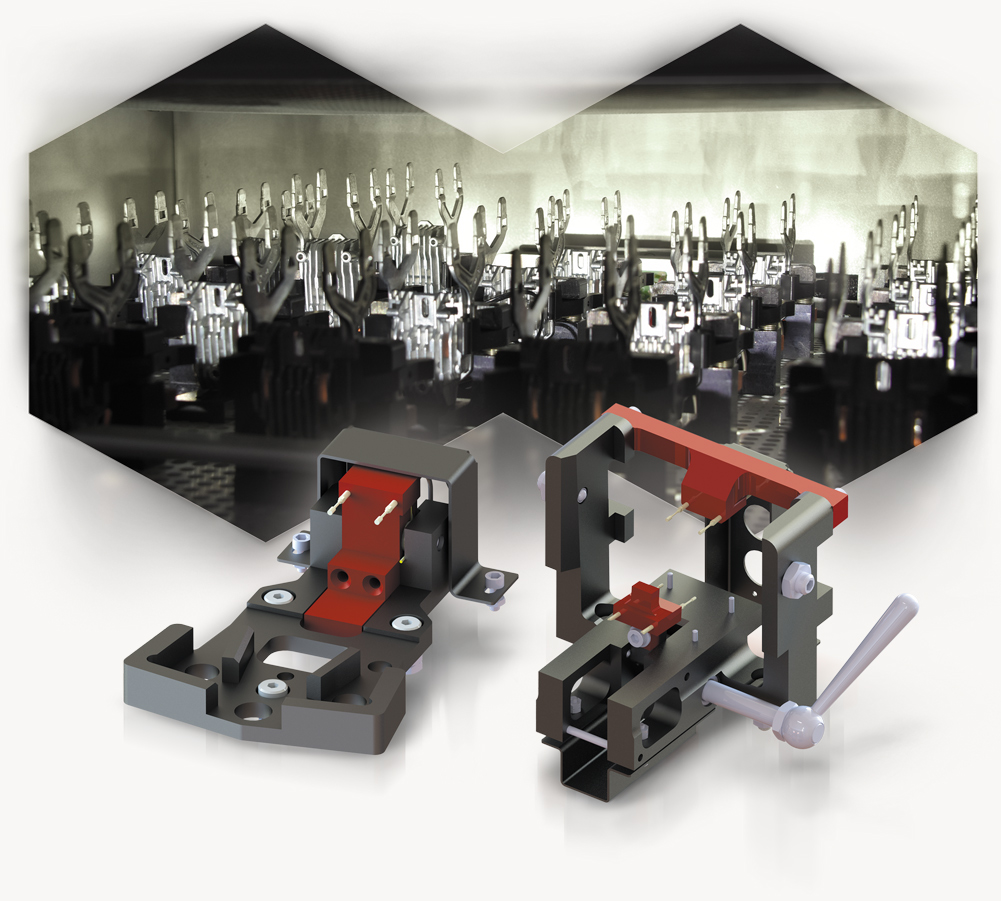

For the functional connectivity testing of the light based in JIG is used measurement device outside of smoke test chamber, operated manually by operator.